PROFESSIONAL GLASS WASHING MACHINES MANUFACTURER

INNOVATION CREATES VALUE SERVICE GENERATES

THE FUTURE

Address: Lunjiao Industrial Road, Lunjiao Town, Shunde District, Foshan City, Guangdong

TEL: 0086-757-27750128

FAX: 0086-757-27880225

E-mail: techwin-yd@info.com

About us

Foshan TECHWIN Glass Technology Co Ltd

was established in 2010 and has become a leading enterprise for glass washing machines. The company has top experts in design and R&D for glass washing solutions. We develop and manufacture high-quality, highly intelligent glass washers. We have exported to more than 40 countries and regions, winning the trust and recognition from many customers.

Washing machine (one step) including drilling, washing, drying

Our company has the right he produs dign and rim, pre Ergive that we work inkom youngin Altheintionsbery more. Woward by this any misaf printing errors. The printing materials may have small difference compared with the real goods, please take the real goods as final, we have the final right to interpret

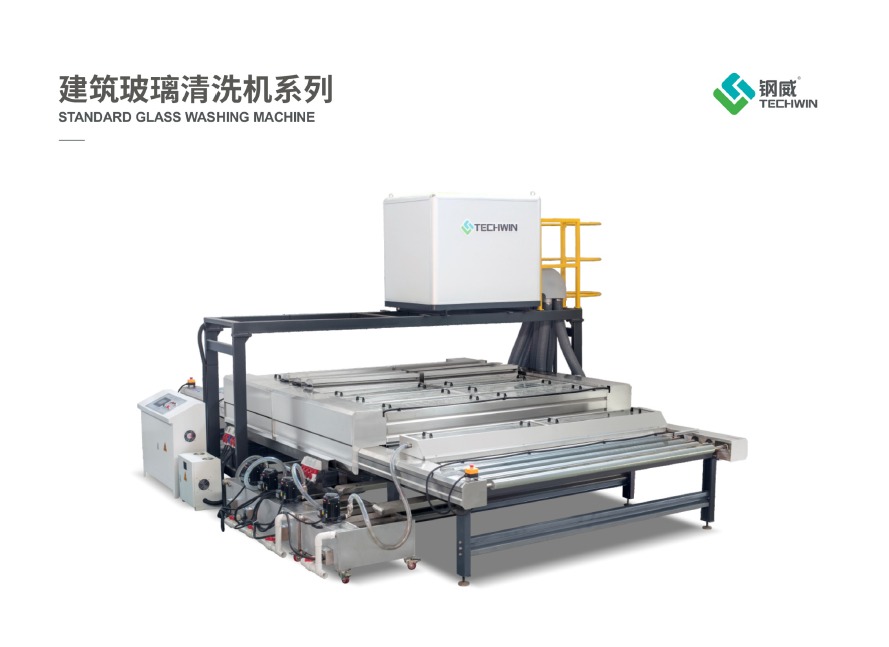

STANDARD GLASS WASHING MACHINE

Three-stage washing machine including drilling, washing and drying the glass

Aluminium machine frame and stainless steel construction for water application parts. With 3 or 4 pairs of brushes to work in high speed and perfect cleaning. Soft brush for Low-E glass, brush diameter is 170mm. Straight and angled air knives are used to eliminate water on surface and edges. Motorized glass thickness adjustment. Integration into edging, laminating or tempering line. Blower invereters as options to save power.

Parts that in contact with water are in stainless steel. Pre washing with individual tank. Washing by 3 cylindrical brushes [2+1] and dry by 2 pairs of air knives. Good separations between washing section to avoid dirty water getting mixed. Blower place on top of the frame to save space and avoid vibration. With PLC, it can work in production lines. Brushes are big and diameter is 170mm. With 4 water tanks for good cleaning. Low noise design.

Parts that in contact with water are in stainless steel. Pre washing with individual tank. Washing by 3 cylindrical brushes [2+1] and dry by 2 pairs of air knives. Good separations between washing section to avoid dirty water getting mixed. Blower place on top of the frame to save space and avoid vibration. With PLC, it can work in production lines. Brushes are big and diameter is 170mm. With 4 water tanks for good cleaning. Low noise design.

Modular production for easy installation and maintenance. With different bridges of disc brushes, each bridge driven by individual motors. Disc brushes used for polishing to make perfect cleaning. Air knives used after disc brushes zone. Cylindrical brushes equipped to wash the glass with clear water. The tanks with valves for auto water supply. Straight and angled air knives to dry glass perfectly. It can be used before coating, digital printing and other processing lines with high requirements.

All stainless steel components and tanks for all water applications. whashing and drying part can be opened for easy maintenance Three pairs of brushes with soft brush for Low-E glass. Each brush is driven by individual motor. Two pairs of angled air knives. Low noise design, blower placed on a platform behind the unloading zone.

Max. Processing size is 1380mm and 1500mm. Processing thickness from 1.6mm to 6mm. Max. Speed of the washing machine reaches 35m/min. There are several sets of pre washing, each set of pre washing has individual tank and pump to provide water. There is air knife set of pre washing ta make sure the water won't enter washing section. Eight pairs of brushes, brush diameter is 150mm and shaft ends of the brushes are in stainless steel. Multi pairs of air knives are used for high speed processing. Washing machine designed for solar processing lines: after edging/drilling, before coating/printing and after tempering.